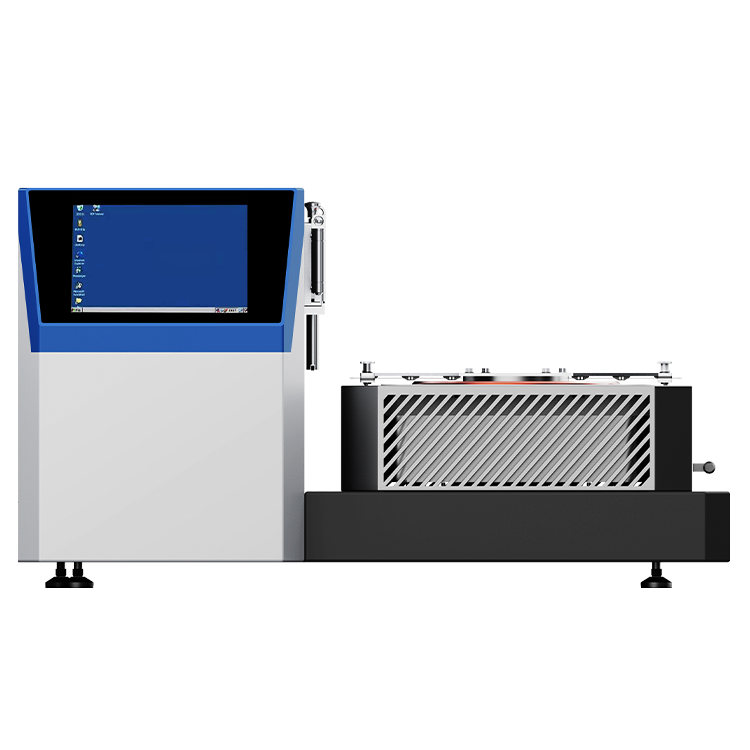

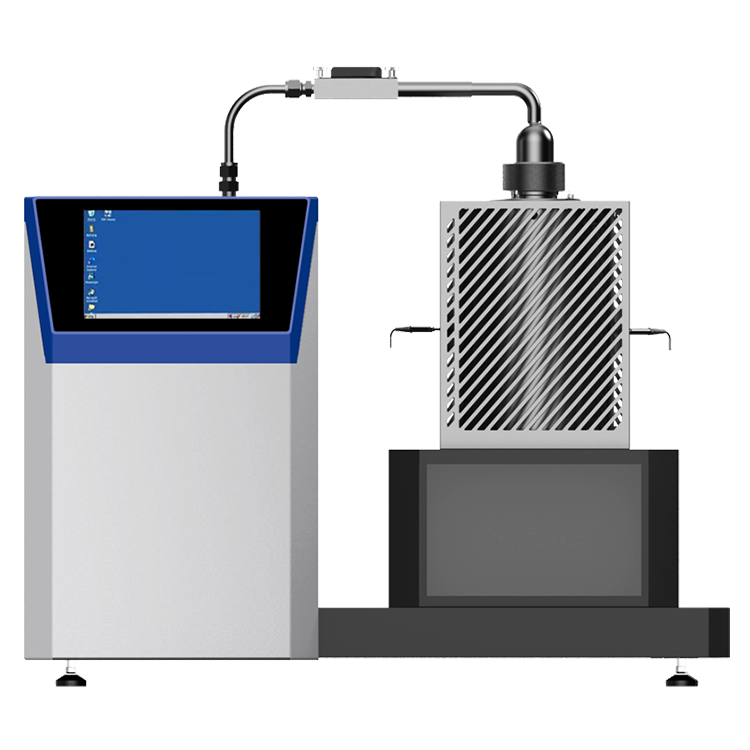

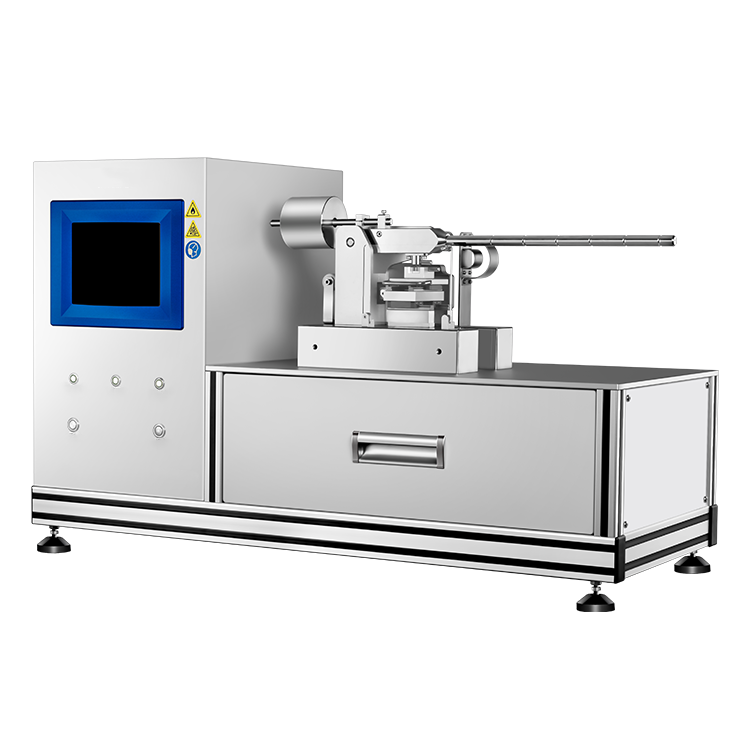

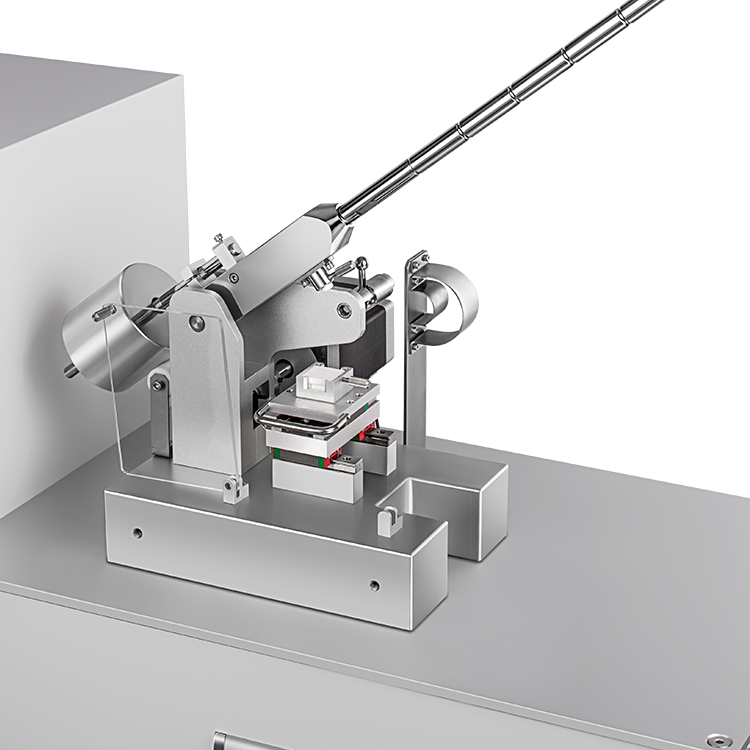

BAM Friction Sensitivity Tester

The BAM Friction Sensitivity Tester precisely determines mechanical friction sensitivity in energetic materials, including primary explosives, high explosives, propellants, and pyrotechnic compositions. This instrument is widely implemented across safety engineering applications, transportation sectors, and research/production facilities such as energetic material laboratories, chemical manufacturing plants, pesticide production units, and military research institutions.

Test Parameters

Mechanical Friction Sensitivity

Applicable Fields

Energetic Materials, Pesticides, Chemical Products

Keywords

Mechanical Friction Sensitivity

Features

Specifications

| Operating Environment | -5°C – 45°C, <95% RH |

| Motor Speed | 140±3 rpm (at maximum load) |

| Load Range | 1~2~5~10~20~40~60~80~120~160~240~360N |

| Load Accuracy | ±0.038 N at 1 N; ±0.048 N at 2 N; ±0.080 N at 5 N; ±0.21 N at 10 N; ±0.45 N at 20 N; ±0.49 N at 40 N; ±0.22 N at 60 N; ±0.27 N at 80 N; ±0.32 N at 120 N; ±0.37 N at 160 N; ±0.43 N at 240 N; ±0.48 N at 360 N. |

| Screen Mesh Specification | 35 mesh (optional) |

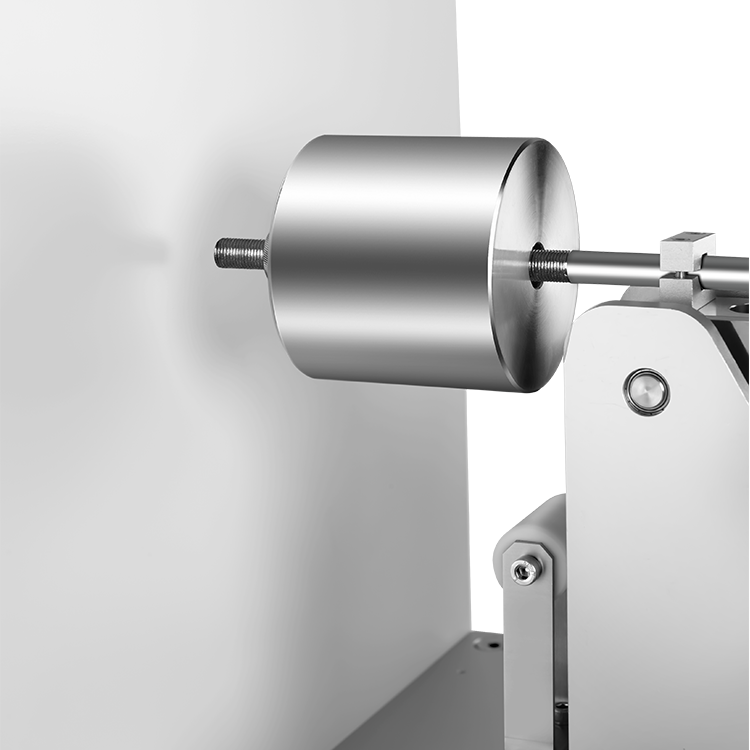

| Measure Dimensions | A cylindrical measure (Ø 2.3 mm × D 2.4 mm) is used for powdery substances, while a rectangular measure (aperture 2 × 10 mm, wall thickness 0.5 mm) is used for paste-like and viscous substances |

| Porcelain Surface Roughness | 9-32 μm |

| Distance between Weight and Porcelain Rod Centers | 11cm, 16cm, 21cm, 26cm, 31cm, 36cm |

| Plate Travel Distance | 10 mm |

| Plate Dimensions (L×W×H) | 25 mm × 25 mm × 5 mm |

| Rod Dimensions (Ø×L) | 10 mm × 15 mm |

Applications

No information!

Videos

No information!

Download

No information!

Q&A

No information!