Thermal Runaway Testing of High Specific Energy NMC 9-Series Lithium-Ion Batteries

In the first half of 2025, the retail penetration rate of new energy vehicles (NEVs) in China reached 50.2%, setting a new historical record for the period. Furthermore, according to statistics, the penetration rate of domestic-brand NEVs in the retail market also hit 48.2% in June. This data indicates that NEVs have gradually become one of the mainstream choices for Chinese consumers. However, the “range anxiety” associated with battery electric vehicles remains a significant concern, which, to some extent, dampens consumer purchase intention and constitutes a key bottleneck for the further market penetration of NEVs.

Within the current technological landscape, increasing the energy density of lithium-ion batteries to extend the driving range of electric vehicles serves as an effective approach to address range anxiety. The industry employs various methods to enhance battery energy density, such as increasing the nickel content in the cathode, optimizing the electrolyte composition or state, or switching the anode material to lithium metal.

Based on our years of practical experience in lithium-ion battery testing, higher energy density typically correlates with a more severe thermal runaway process.This characteristic can be quantified and observed through data such as the sample’s temperature rise rate, peak temperature during thermal runaway, and video recordings of the event. Thermal runaway testing of high-energy-density lithium-ion batteries has always been challenging in adiabatic calorimetry. Due to their rapid temperature rise, high peak thermal runaway temperature, short duration, and intense energy release, key data points can be missed if acquisition is not timely, and the accuracy of test data may be compromised, potentially even damaging the testing equipment.

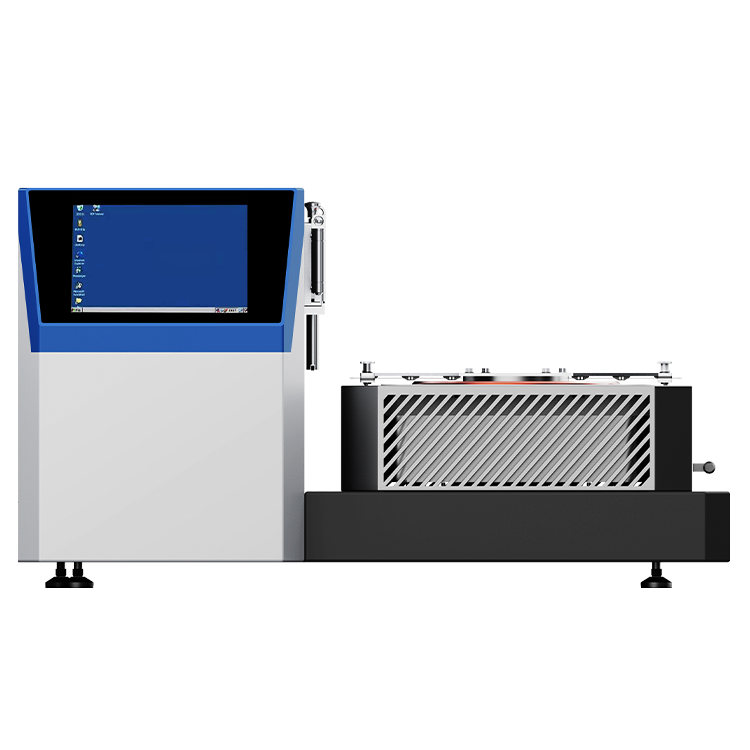

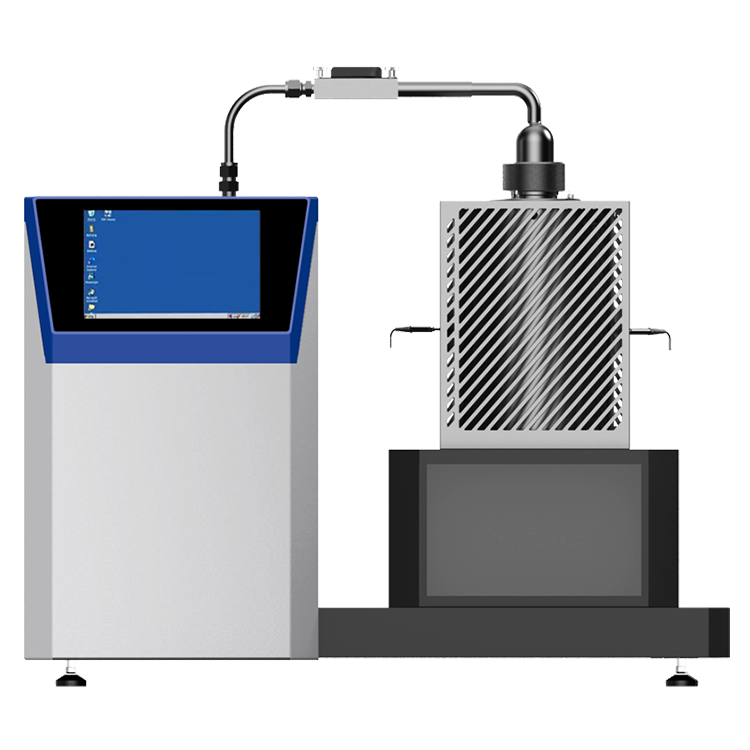

The BAC-800BE Large Battery Adiabatic Calorimeter is designed to effectively address the technical challenges of testing high-energy-density lithium-ion battery thermal runaway. It incorporates three core advantages: a sealed chamber shell compliant with the GB 150 pressure vessel standard, a variable sampling rate (up to 100 Hz), and temperature measurement using Type B thermocouples (with a measurement range of 900–1800 ℃).

Experimental Scheme

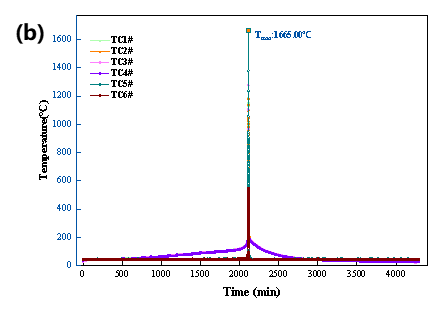

This experiment employed the BAC-800BE to conduct an adiabatic thermal runaway test on a 180 Ah NMC 9-Series lithium-ion battery. N-type and B-type thermocouples were positioned at various points on the battery for temperature measurement, with fixtures ensuring consistent and tight contact. A high-frequency pressure sensor was used to collect pressure data. Finally, a high-speed camera, mounted outside the instrument chamber, provided real-time monitoring of the battery’s thermal runaway process. This setup enabled comprehensive multi-dimensional monitoring and analysis.

Experimental Results

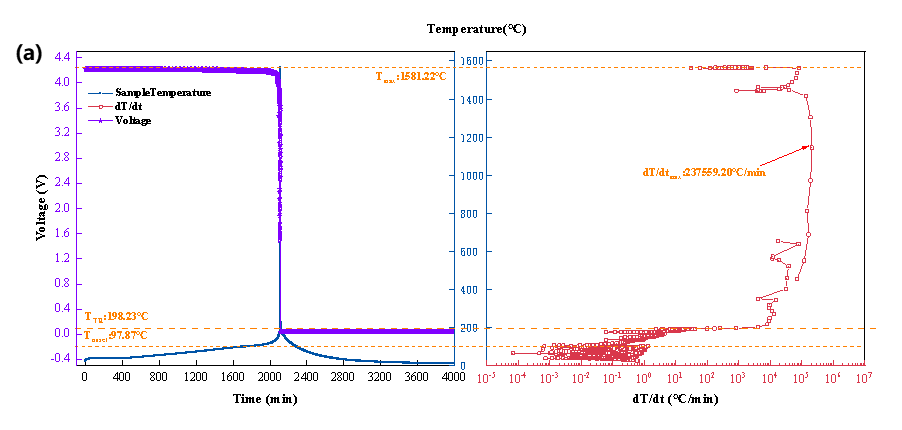

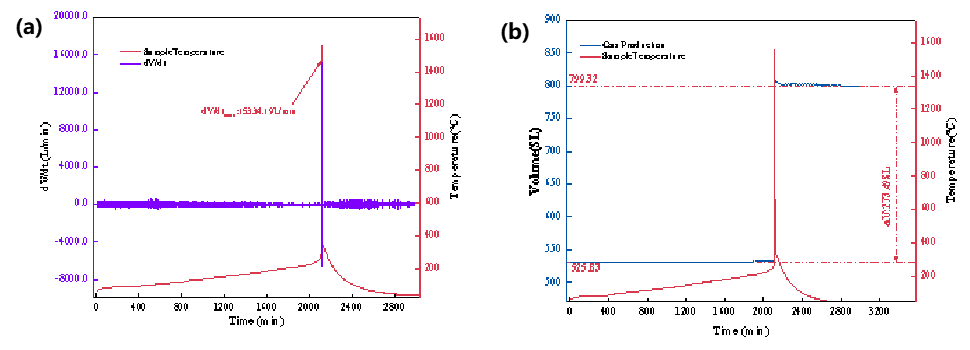

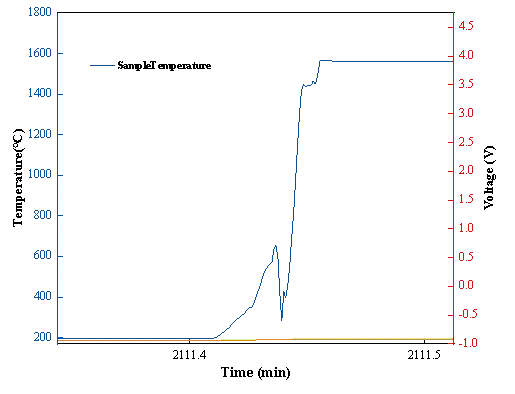

Analysis of the temperature data in Figure 2 and the gas evolution rate and volume data in Figure 3 reveals an extremely violent thermal runaway event. A close examination of the sample temperature curve shows that the entire thermal runaway process, from onset to conclusion, lasted less than 3 seconds, during which the temperature increased by over 1300 ℃. The temperature rise rate exceeded 200,000 ℃/min. Meanwhile, the gas data indicates that the peak gas evolution rate during thermal runaway surpassed 15,000 L/min, demonstrating the intense impulsive force characteristic of lithium battery combustion and explosion.

Although the T1 and T2 temperatures of this battery remain in a high range, they show significant improvement compared to the first generation. This optimization in key metrics demonstrates a systematic advancement in safety performance, providing strong support for the safe application of high-energy-density batteries.

Conclusion

This experiment, utilizing the BAC-800BE Large Battery Adiabatic Calorimeter for thermal runaway testing of a large-capacity, high-energy-density lithium-ion battery, successfully demonstrated the extreme severity of thermal runaway in such batteries while simultaneously verifying the instrument’s reliable performance under these demanding conditions.