Thermal Runaway Total Heat Release of 18650 Lithium-Ion Batteries

The total heat release during battery thermal runaway serves as a critical indicator for quantifying its destructive potential, providing essential guidance for battery thermal management design and safety control. Conventional adiabatic calorimeters heavily rely on precise specific heat capacity measurements, yet their inability to track rapid temperature changes during instantaneous thermal runaway often leads to calorimetric errors and incomplete heat release data.

The automatic oxygen bomb calorimeter is an instrument based on isothermal calorimetry principles for measuring material combustion heat. The system operates by submerging a sealed oxygen bomb in a water-filled inner chamber. Through combustion of a precisely measured combustible sample within the bomb, the released heat transfers to the surrounding water, enabling calculation of the material’s heat release based on measured water temperature variations.

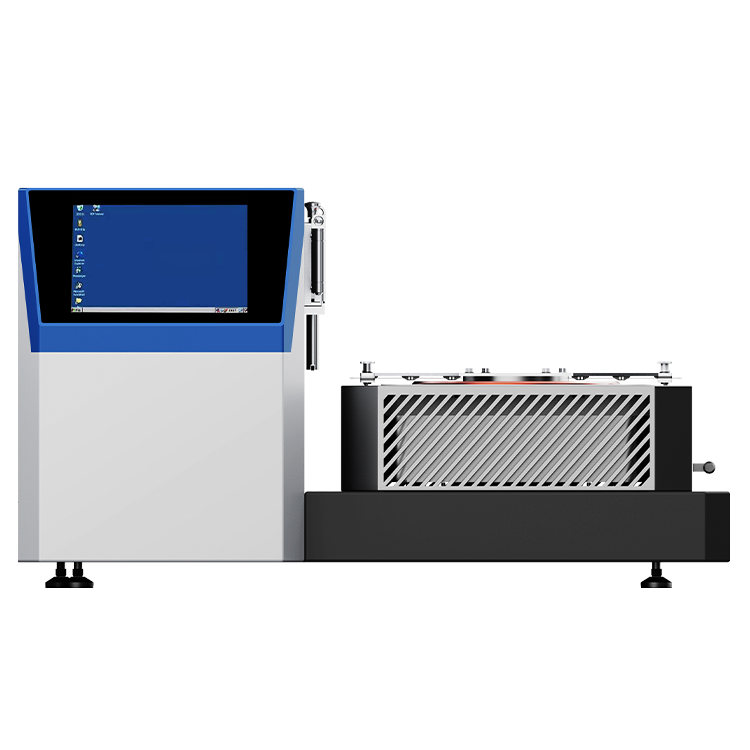

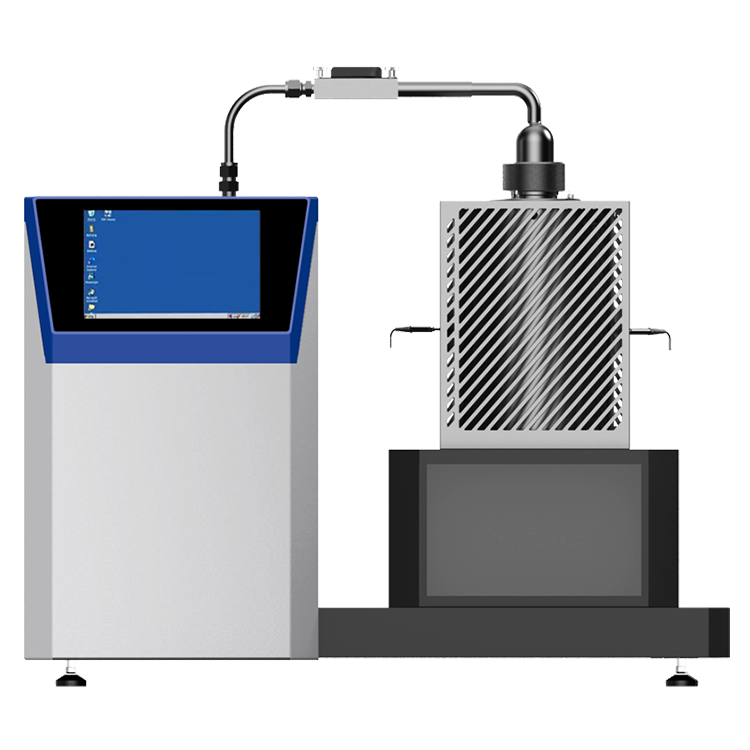

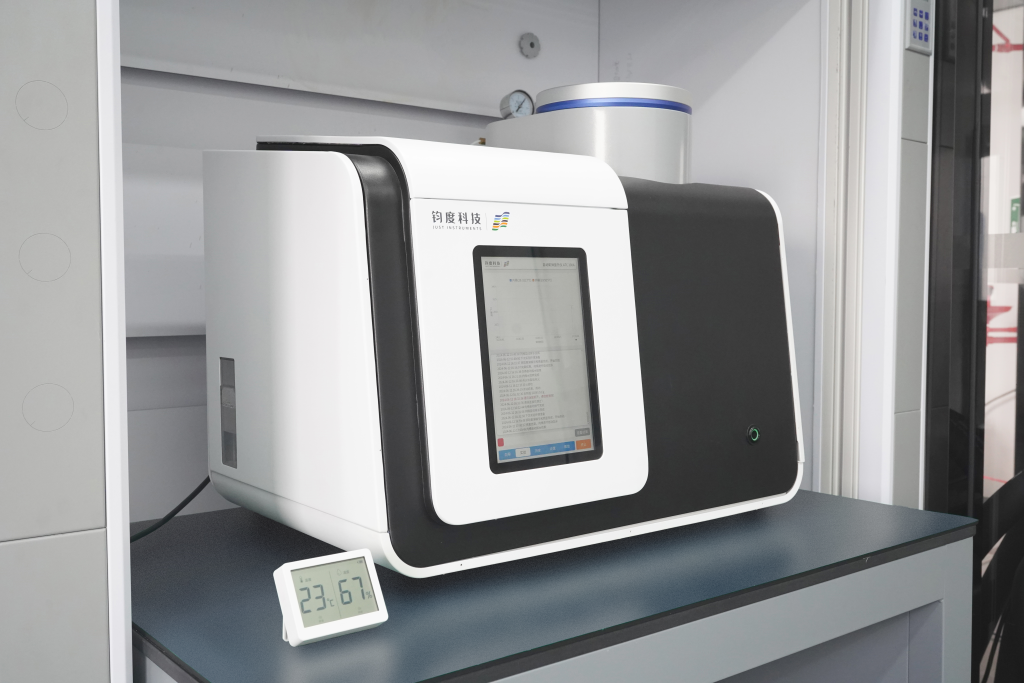

Figure 1. Customized ATC 300AE Oxygen Bomb Calorimeter

This study employed a customized ATC 300AE Oxygen Bomb Calorimeter to measure the total heat release of 18650 NCM lithium-ion batteries triggered into thermal runaway by heating elements in an inert atmosphere. The results demonstrate: 45,896.9 J for fully discharged cells and 67,620.7 J for fully charged cells.

Experimental Conditions

- Test instrument: Customized ATC 300AE Oxygen Bomb Calorimeter

- Test method: GB/T 213-2008

- Test sample: 18650 NCM lithium-ion battery

- Thermal runaway trigger method: heating element triggering (20V/5A)

Testing Procedure

- Step 1: Prepare 18650 NCM lithium-ion batteries at both fully discharged (0% SOC) and fully charged (100% SOC) states. Weigh each battery and record its voltage.

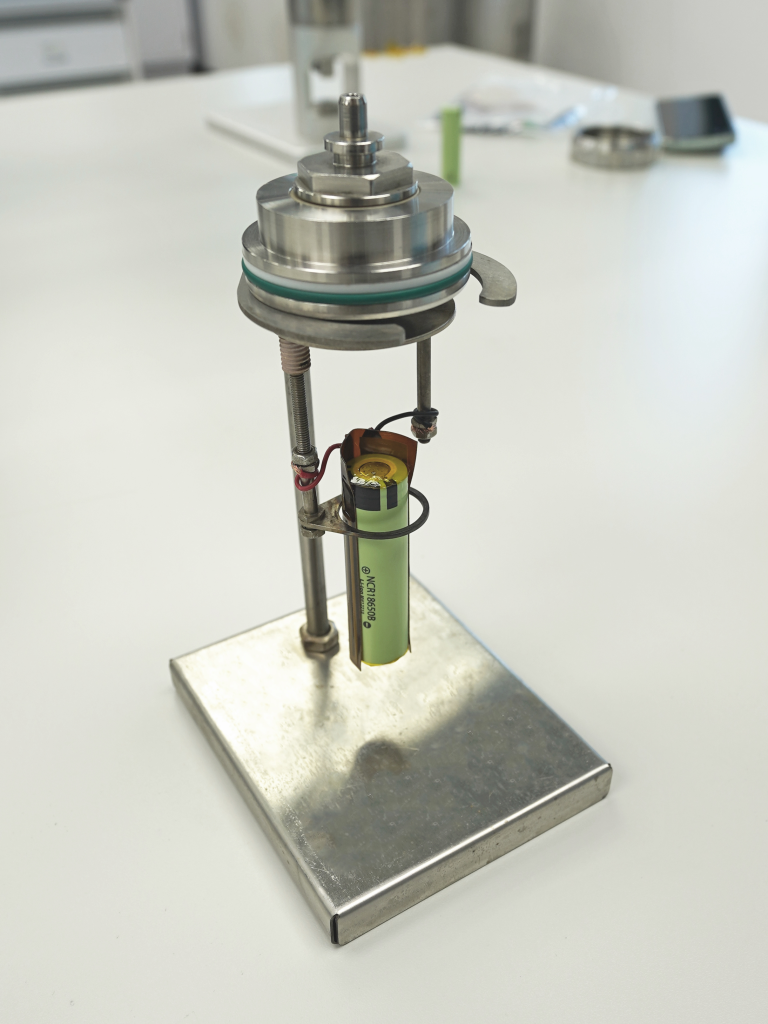

- Step 2: Attach the heating element to the battery surface, ensuring full contact. Connect the heating wires and assemble the battery into the oxygen bomb chamber as shown in Figure 2.

Figure 2. Battery assembly inside the oxygen bomb

- Step 3: Suspend the assembled oxygen bomb in the instrument. Set experimental parameters and input sample information.

- Step 4: Initiate the test. The system will automatically perform measurements.

- Step 5: Upon test completion, remove the oxygen bomb and clean the chamber.

- Step 6: Repeat the test and record all experimental data.

Experimental Result

The experimental setup is shown in Figure 3. The system triggers thermal runaway in 18650 NCM lithium-ion batteries internally via heating elements, and the measured combustion heat minus the input heating energy yields the battery’s total heat release.

Figure 3. Customized ATC 300AE Oxygen Bomb Calorimeter

As presented in Table 1, the mean total heat release from three repeated tests of fully discharged batteries was 45,896.9 J with a relative standard deviation (RSD) of 3.25%, while fully charged batteries exhibited 67,620.7 J total heat release.

| 18650 Lithium-ion Battery | 0% SOC (Empty) | 100% SOC (Full) | ||

| No. | a | b | c | d |

| Voltage (V) | 3.596 | 3.596 | 3.596 | 4.130 |

| Initial Mass (g) | 45.106 | 44.963 | 44.994 | 45.293 |

| Final Mass (g) | 24.440 | 32.804 | 27.293 | 19.370 |

| Mass Loss Ratio | 46% | 27% | 39% | 57% |

| Combustion Heat (J) | 68483.1 | 58791.2 | 68768.5 | 78604.5 |

| Heating Element Heat (J) | 21331.5 | 14540.3 | 22480.4 | 10983.8 |

| Battery Total Heat Release (J) | 47151.6 | 44250.9 | 46288.1 | 67620.7 |

| Mean Heat Release (J) | 45896.9 | – | ||

| Heat Release RSD | 3.25% | – | ||

| Table 1. Total heat release test results for 18650 lithium-ion batteries | ||||

In the aforementioned tests, the varying post-test conditions and masses of the three fully discharged batteries after thermal runaway events may represent the primary cause of deviations in total heat release measurements.

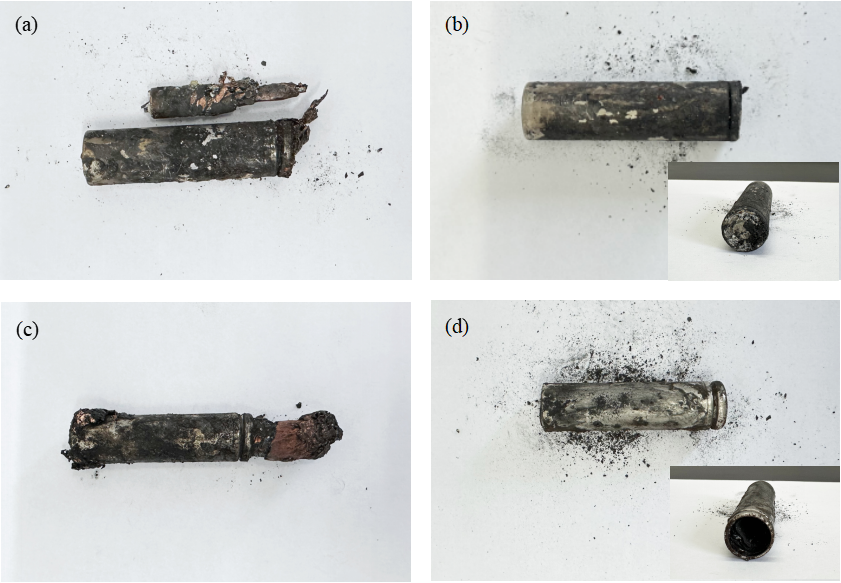

The post-test battery conditions are shown in Figure 4: Battery b (0% SOC) remained relatively intact after combustion, while Batteries a and c (0% SOC) exhibited similar states with significant ejection of internal components. Battery d (100% SOC) demonstrated complete combustion, leaving essentially only the outer casing.

Figure 4. Post-thermal runaway conditions of 18650 lithium-ion batteries: (a/b/c) at 0% SOC and (d) at 100% SOC

The test results demonstrate that Battery b (0% SOC) exhibited the lowest total heat release, while Batteries a and c (0% SOC) showed comparable results, and Battery d (100% SOC) yielded the maximum heat output. A positive correlation exists between mass loss during thermal runaway combustion and total heat release – greater mass loss ratios correspond to higher heat release values.

Experimental Conclusions

This study employed heating-element-triggered thermal runaway combined with a customized ATC 300AE oxygen bomb calorimeter to determine the total heat release of 18650 NCM lithium-ion batteries at both fully discharged and fully charged states, providing critical fundamental parameters for lithium battery thermal management design and fire safety assessment.